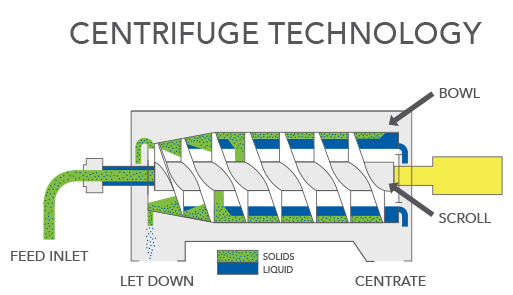

RS Centrifuge Technology rotates at variable high speeds to allow for different material densities to be separated by way of centrifuge forces. This variable high speed ensures that the optimum rotation speed is set to ensure the maximum separation will occur when using our equipment. This technology has been used to separate both liquids for other liquids with different densities as well as separation of liquids from solids.

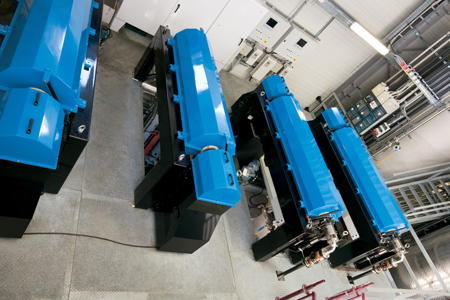

The CRS Centrifuge Technology consists of a rotating drum with an independently operating rotating screw conveyor inside the unit. As process fluid is fed into the unit’s mixing chamber flocculation material can be added to assist in the separation process. The Centrifuge has two outlets, one for the heavier material that is thrown through the holes during the centrifugation process. The lighter material is transported to the other outlet. Some applications require special mounting of the centrifuge in order to meet system requirements, consequently CRS has develop automated lifting stands as well as mobile units mounted inside of trucks.