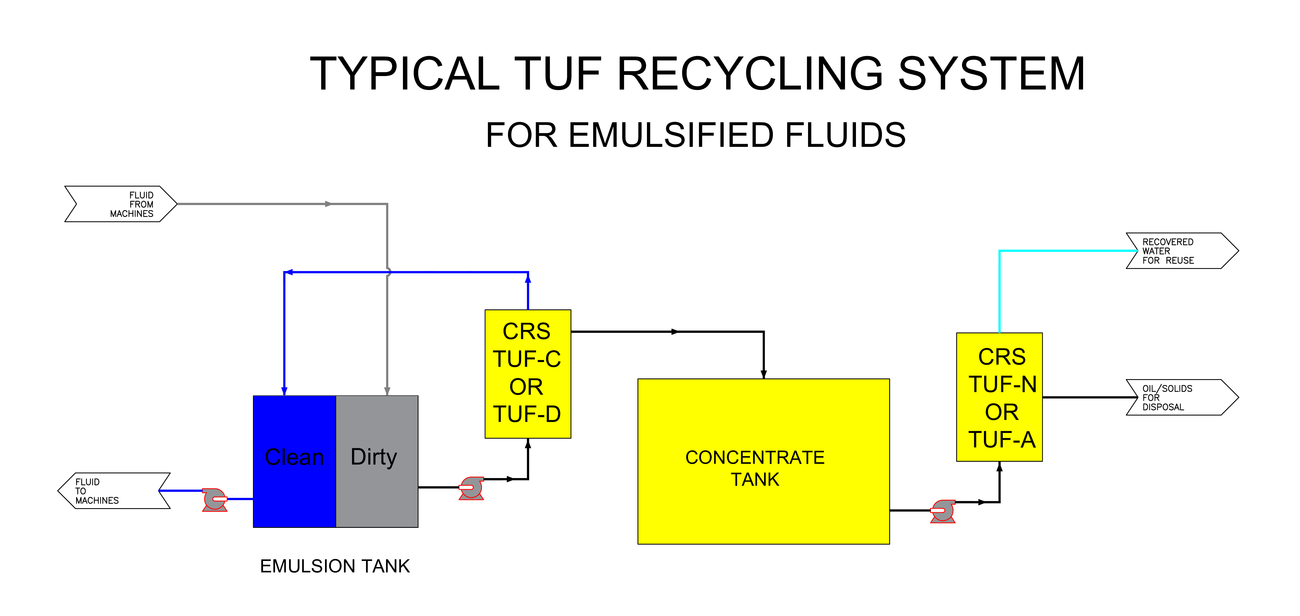

Ultrafiltration is a highly effective separation technology used by CRS Reprocessing to treat industrial fluids, recover valuable components, and improve overall process efficiency. Similar to microfiltration, ultrafiltration removes macromolecules, small particles, suspensions, and emulsions from liquid streams. The distinction between microfiltration and ultrafiltration lies primarily in membrane pore size. Membranes with pore diameters ranging from a few micrometers down to 0.1 micrometers are considered microfiltration, while membranes with pores between 0.1 and 0.01 micrometers fall into the ultrafiltration category. Ultrafiltration typically operates at pressures between 0.5 and 20 bars, depending on the application and fluid characteristics.

The primary mechanism of ultrafiltration is sieving, where particles larger than the average diameter of the membrane pores are retained, while smaller components pass through. In addition to this size-based separation, solubility and diffusion effects contribute to the overall filtration process. This combination allows CRS Reprocessing to achieve precise separation of contaminants, emulsions, and suspended solids, while recovering clean fluids for reuse.

CRS Reprocessing applies advanced engineering to optimize ultrafiltration systems for each client. Membrane construction and coating are critical technical innovations that distinguish our solutions. By reducing fouling—the accumulation of contaminants that can clog membranes—by up to 50 percent, CRS Reprocessing achieves higher feed rates, more consistent throughput, and stable product quality. This innovation ensures that ultrafiltration systems maintain peak performance over extended operation periods, reducing downtime and maintenance requirements.

Depending on the application, CRS selects the appropriate membrane pore size and configuration to meet process requirements. Our expertise ensures that ultrafiltration systems integrate seamlessly with existing operations, whether for industrial wastewater treatment, emulsion recovery, or fluid purification. The result is improved resource efficiency, reduced waste, and optimized operational performance.

Partnering with CRS Reprocessing for ultrafiltration solutions provides access to innovative technologies, reliable engineering, and dedicated support. Our ultrafiltration systems enable manufacturers to separate contaminants effectively, recover valuable fluids, and maintain consistent product quality, all while minimizing operational costs and environmental impact. CRS Reprocessing turns ultrafiltration into a strategic advantage, helping clients achieve sustainable, high-efficiency operations.

CRS has a large pilot test tool kit including our latest mobile TUF pilot test trailer that can be brought to the customer’s site.